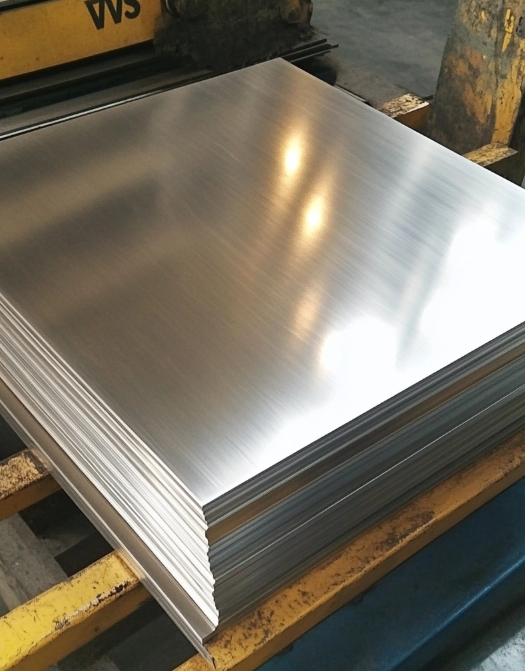

Our wholesale stainless steel sheet is used in a variety of industries and can be cut, bent, and formed into different shapes and sizes for applications such as appliances, roofing, and construction. Normandy specializes in the production and supply of high-quality wholesale stainless steel sheet metal as well as providing custom stainless steel sheet. Various grades of products include wholesale 304 stainless steel sheet, wholesale 316 stainless steel sheet, and efficient shipment. Dedicated to excellence, our stainless steel sheet wholesale is reliable, durable, and adheres to the highest industry standards. Choose Normandy Metal as your SS sheet supplier, with the strength to cover the type of stainless steel sheet metal you need.

Stainless Sheet Factory, Custom Stainless Steel Sheets

Our wholesale stainless steel sheet is used in a variety of industries and can be cut, bent, and formed into different shapes and sizes for applications such as appliances, roofing, and construction. Normandy specializes in the production and supply of high-quality wholesale stainless steel sheet metal as well as providing custom stainless steel sheet. Various grades of products include wholesale 304 stainless steel sheet, wholesale 316 stainless steel sheet, and efficient shipment. Dedicated to excellence, our stainless steel sheet wholesale is reliable, durable, and adheres to the highest industry standards. Choose Normandy Metal as your SS sheet supplier, with the strength to cover the type of stainless steel sheet metal you need.

Stainless Sheet Factory, Custom Stainless Steel Sheets

Normandy Metal, the well-established stainless steel sheet factory, offers a wide range of wholesale stainless sheet metal to cater to your specific needs:

304 stainless sheet metal:The most commonly used custom stainless steel panels. This stainless steel metal plate is known for its excellent corrosion resistance, formability, and ease of cleaning, making it ideal for a variety of applications, including kitchen appliances, sinks, and architectural panelling.

316 stainless sheet:An upgrade from the 304 stainless steel sheet. But its price is higher than 304 stainless sheet price. It has superior corrosion resistance, especially against chlorides and other industrial solvents. This makes it perfect for use in marine environments or in chemical processing industries.

321 stainless steel sheet. This type of stainless steel sheet is stabilized with titanium, providing excellent resistance to intergranular corrosion. It is commonly used in high-temperature environments, such as those found in jet engine parts and heat treatment equipment. The unique properties of this stainless steel metal plate make SS plate suppliers closely connected with the aerospace, oil and gas industry.

Chemical Composition: 304 SS sheet metal contains 18% chromium and 8% nickel while 316 stainless steel sheet metal contains 16% chromium, 10% nickel and 2% molybdenum.

Corrosion Resistance: Both 304 and 316 wholesale stainless steel sheet metal are corrosion-resistant, but 316 wholesale stainless steel sheet provides better resistance to pitting and corrosion from chloride solutions, making it ideal for marine or harsh chemical environments.

Weldability: Both wholesale 316 stainless steel sheet and 304 are weldable, but 316 requires more attention during welding to ensure proper corrosion resistance.

Temperature Resistance: Both 304 and 316 wholesale stainless steel sheet have good temperature resistance, but 316 provides better performance under high-temperature conditions.

Strength and Durability: 316 wholesale stainless steel sheet is generally stronger and more durable than 304 due to its higher nickel, chromium, and molybdenum content.

Professional Stainless Steel Sheet Company,

Providing Various Surface Treatment Options.

1. 2B Surface Finish: This is a smooth, matte finish that is used for general applications.

2. Stainless Steel No 4 Finish: This is a brushed finish that creates a textured, satin-like appearance and is often used for decorative or architectural applications.

3. No. 8 finish: This is a mirror finish that provides a highly reflective surface and is often used for decorative applications.

4. BA finish: This is a bright annealed finish that gives bright annealed stainless steel a highly reflective surface that is similar to a mirror finish.

5. Titanium-coated finish: This finish is achieved through a process of coating the stainless steel sheet with a layer of titanium, which can create a range of colors and textures.

6. Colored finish: This finish involves coloring the stainless steel sheet through a process of vapor deposition, electroplating, or painting.

7. Bead-blasted finish: This finish is created by blasting the surface of the stainless steel sheet with small glass beads, creating a uniform matte texture.

8. Etched finish: This finish involves etching a pattern or design into the surface of the stainless steel sheet, creating a decorative or artistic effect.

When you custom stainless steel sheets from SS sheet manufacturer, the choice of finish will depend on the intended application, aesthetic requirements, and desired texture or appearance.

▶ Deliver exceptional quality and precision with state-of-the-art manufacturing facilities.

▶ Offer a diverse bulk sheet metal range that meets the needs of various industries, from construction to automotive.

▶ Provide unparalleled customer service and customized solutions tailored to individual client requirements.

▶ Implement sustainable practices and eco-friendly initiatives, dedicated to environmental responsibility.

▶ Lead the industry with continuous innovation and a strong focus on maintaining high standards.

1. Regular cleaning: Stainless bulk sheet metal should be cleaned on a regular basis to remove dirt, grime or any other foreign substances that can contribute to corrosion. Use a mild soap and water solution or a specialized stainless steel cleaner to remove any residue or contaminants.

2. Avoid scratches: Avoid using abrasive tools, such as steel wool, on stainless steel sheets as they can cause scratches. Scratches can trap dirt and lead to corrosion.

3. Soft cleaning tools: Use non-abrasive cleaning tools, such as soft cloths, sponges, or scrubbers. This will prevent scratches and damage to the stainless steel surface.

4. Avoid harsh chemicals: Avoid using harsh chemicals, such as bleach, ammonia, or chlorine, on stainless steel sheets as these can damage the surface finish and cause discoloration or corrosion.

5. Proper storage: Stainless bulk sheet metal should be stored in a cool and dry place to prevent moisture and humidity that can lead to rust or other types of corrosion.

6. Polishing: To maintain the shine of stainless steel sheets, some applications may require polishing using a specialized stainless steel polish. This helps to remove any stains and restore the shine of the surface finish.

We accept drawings and samples in multiple formats to provide you with customized bulk sheet metal services. The formats you can submit include but are not limited to: AutoCAD files (DWG, DXF), PDF, JPEG, PNG, and hand-drawn scans.

Detail-oriented SS sheet supplier: After confirming every detail of the drawing, we will process it accurately for you

Please understand if there is any uncertainty or delay in the custom stainless steel sheet.

We have a large inventory of wholesale stainless steel sheet metal, fast delivery, to ensure project progress.

We are a professional SS sheet supplier, providing technical support and consultation, solving design and construction problems, and ensuring satisfaction.

Custom stainless steel sheet support. Various surface treatments to meet different design requirements. Comply with international standards, quality is guaranteed.