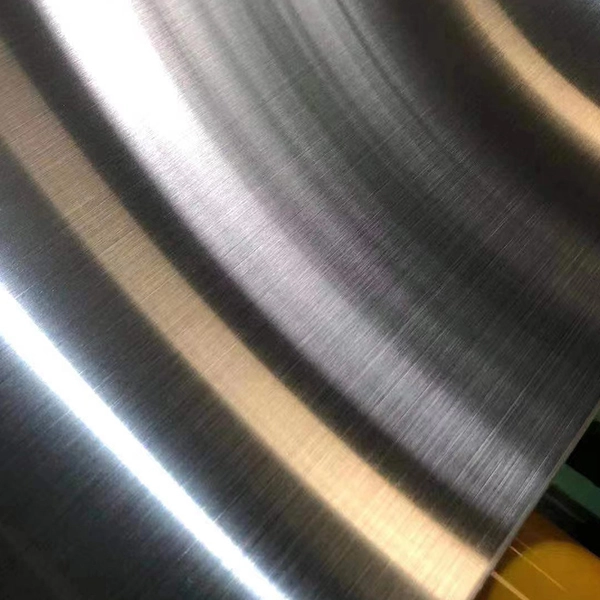

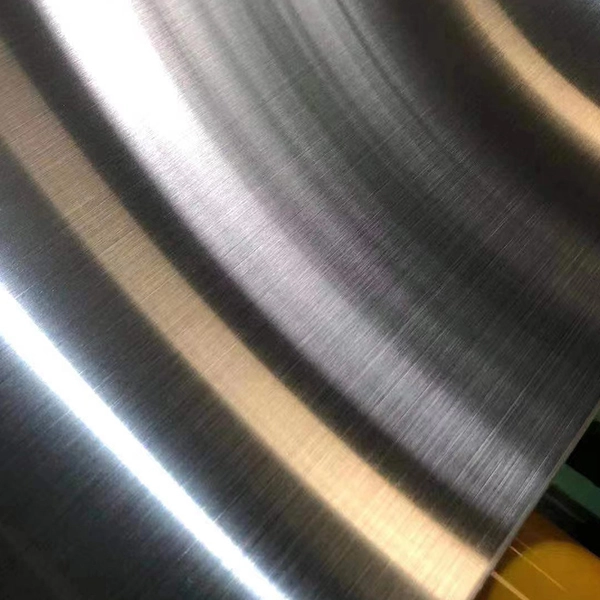

201 NO.4 Stainless Steel is a low-cost alternative to other stainless steel grades. It contains a higher amount of manganese and nitrogen, which gives it improved strength and corrosion resistance. This steel has a smooth, brushed finish and is commonly used in applications such as decorative items, architectural projects, and furniture. The "No 4" surface is created by cutting the surface with an abrasive belt to remove a very small amount of metal without affecting its thickness. For architects and designers, the No 4 finish provides panels with low gloss and optimum apparent flatness.

| No.1 Finish Stainless Steel Plate Grades | 202 / 304 / 304L / 304H / 309S / 310S / 316 / 316L / 316Ti / 317L / 321 / 321H / 347 / 347H / 904L etc. UNS No. - UNS S30400, UNS S30403, UNS S31008, UNS S31620, UNS S31603, UNS S31603, UNS S31635, UNS S31703, UNS S32100, UNS S34700, UNS S34709, UNS S8904 EN No. - 1.4301, 1.4307, 1.4845, 1.4401, 1.4404, 1.4571, 1.4438, 1.4541, 1.4550, 1.4551, 1.4539 | |||

| Standard | JIS, AISI, ASTM, GB, EN | |||

| Place of Origin | China | |||

| Certification | ISO | |||

| Thickness Range | 0.3-3.0MM | |||

| Thickness Tolerance | ± 5%MM | |||

| Surface Classification | 2B | |||

| Grade | / | |||

| Width | 1250 MM / 1500 MM / 2000 MM / 04 Feet / 05 Feet and Custom Cut Width as Per Requirement | |||

| Length | Steel Plate Length 2400 MM / 2420 MM / 6000 MM / 08 Feet / 10 Feet / Coil Cut and Custom Cut Length as Per Requirement | |||

| Technique | Cold Rolled | |||

| Quality | High Quality Inspection | |||

| Application | It's the product of grinding with NO.150-180 abrasive belt. Having better gloss, discontinuous coarse lines, and thinner stripes than NO.3. For interior and exterior decoration materials. electrical appliances, kitchen equipment, video equipment, etc.. | |||

| Brief Introdction | It features short, parallel polish lines and is the easiest to maintain stainless steel finish. Depending on the requirements of the application, the final finish can range in size from 120 to 320 mesh. (The higher the grit, the finer the polish lines and the more reflective the surface.) Surface roughness is typically Ra 25 microinches or less. | |||

The No. 4 Standard Satin finish (32 Ra Max) is often referred to as the "workhorse finish" and is one of the most common finishes applied to architectural and process vessels. The consistent satin appearance meets stringent hygiene requirements and is easy to blend. This hassle-free finish is universally acceptable for process equipment systems and tank wet surfaces and can meet high visual aesthetic requirements. Available in a variety of options and customizations, the No. 4 Standard Satin finish is a versatile, high-quality finish suitable for many applications.

Suitable for construction or process applications

Refined, consistent satin look

Generally accepted for process equipment systems and tank wetted surfaces

Aerospace

Interior and exterior architecture

Chemical

Cosmetics

Fossil and solar energy

Food/dairy/beverage

Microchip manufacturing

Nuclear energy

Water treatment

Vacuum Chambers