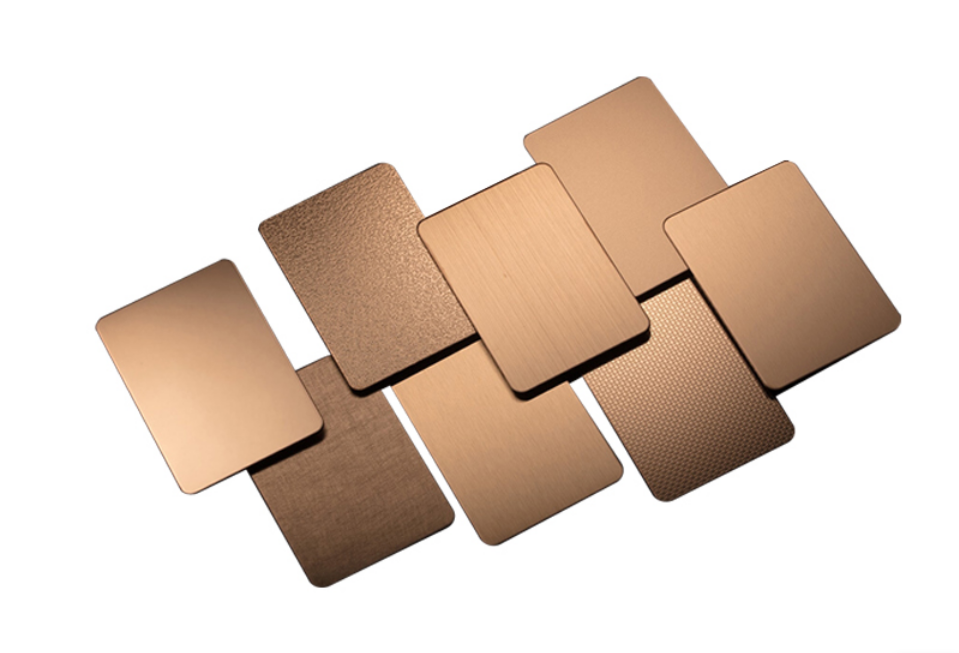

In modern industry and design, golden stainless steel plates have become the first choice of many B-end buyers because of their noble appearance and excellent performance. So, how to plate stainless steel plates with gold? First, you need to prepare stainless steel plates, gold plating liquid, cleaning agents and electroplating equipment. Proceed as follows:

Use a professional cleaner to thoroughly clean the stainless steel surface to ensure that it is free of oil, dust and other impurities.

Dip the stainless steel plate into an acidic solution for pickling to remove the oxide layer on the surface.

Put the stainless steel plate into the gold plating solution, connect the power supply, and start electroplating. Plating time and current intensity need to be adjusted according to specific requirements.

After electroplating is completed, the stainless steel plate is taken out, cleaned and dried, and finally polished to obtain a bright golden surface.

It is more difficult to plate gold on ordinary stainless steel plates (such as 201 2b stainless steel). Pretreatment complexity: There may be a thick oxide layer and impurities on the surface of 201 stainless steel, requiring more complex pretreatment steps, such as stronger pickling or mechanical grinding. Surface finish: The surface flatness and finish of 201 stainless steel is not as good as that of 304 stainless steel, and more polishing and processing steps are required to achieve the ideal gold plating effect. Electroplating parameter control: The chemical stability and electrical conductivity of 201 stainless steel are not as good as 304 stainless steel. Finer parameter control is required during the electroplating process to ensure the uniformity and adhesion of the gold plating layer. In comparison, the difficulty of gold plating on 304 BA stainless steel is relatively low, because its material properties and simplicity of surface treatment make the gold plating process smoother.

In addition to stainless steel, ordinary steel can also be gold-plated to improve its appearance and corrosion resistance. Here are the basic steps for gold plating steel:

1. Surface cleaning: Use detergent to thoroughly clean the steel surface to remove oil and impurities.

2. Pickling treatment: The steel is immersed in an acidic solution to remove the oxide layer and rust on the surface.

3. Nickel plating bottom layer: A layer of nickel is first plated on the surface of the steel to improve the adhesion and durability of the gold plating layer.

4. Gold plating treatment: Put the steel into the gold plating solution, connect the power supply, and perform electroplating. Adjust plating time and current intensity according to needs.

5. Post-processing: After electroplating is completed, clean, dry and polish to obtain a bright golden surface.

Through the above steps, you can transform ordinary steel into high-end golden steel, which is widely used in decoration, construction, electronics and other fields.

Electroplating Stainless steel gold plating is a technique that covers the surface of stainless steel with a layer of gold through an electrochemical process. First, the stainless steel needs to be thoroughly cleaned to remove dirt, grease and oxides from the surface, usually using chemical cleaners or ultrasonic cleaning. Next, it is pickled to slightly roughen the surface of the stainless steel so that the gold layer can adhere better. The stainless steel object is then immersed in a plating solution containing gold ions, and an electric current is passed to deposit the gold ions on the stainless steel surface. The stainless steel object acts as the cathode, while the gold or other conductive material acts as the anode. After the desired thickness of the gold layer is achieved, the object is removed from the plating solution and rinsed with water to remove residual chemicals, followed by drying. Finally, the gold-plated stainless steel may be additionally polished or coated with a protective layer to enhance its appearance and durability. This technology is widely used in jewelry, electronics, and decorative products, providing a luxurious gold appearance while maintaining the strength and durability of stainless steel.

Occasionally, you may need to remove the gold plating from stainless steel, rework it, or replace the plating. So, how to remove gold plating safely and effectively? Here are some common methods:

Chemical solution: Use a special deplating solution to effectively remove the gold coating on the surface of stainless steel. Wear protective equipment when operating to ensure safety.

Mechanical grinding: Use sandpaper or a grinder to grind the stainless steel surface to remove the gold coating layer by layer. This method is suitable for thicker coatings, but care needs to be taken to control the grinding intensity to avoid damaging the stainless steel substrate.

Electrolytic deplating: Put the stainless steel plate into a specific electrolyte to remove the gold plating through electrolytic reaction. This method is highly efficient, but requires specialized equipment and operating skills.

No matter which method you choose, you need to pay attention to operational safety and environmental protection to ensure that the deplating process goes smoothly.

Whether it is gold-plated stainless steel or ordinary steel, Normandymetal stainless steel products company can provide you with professional technical support and high-quality products. Choose us to help you stand out in the market competition and win more business opportunities!