The supply demand of 300 series stainless steel is very high, mainly because of its excellent corrosion resistance, processability and wide range of applications. They are widely used in fields such as food processing, chemical industry, construction, medical equipment and marine engineering.

300 Series Stainless Steel is a group of austenitic stainless steels known for their excellent corrosion resistance, formability, and weldability. Common grades include 304 and 316, which contain chromium and nickel. These steels are widely used in various industries, including food processing, chemical, and marine applications.

Ensure that the purchased stainless steel meets specific chemical composition and mechanical performance requirements, such as the composition and characteristics of specific grades such as 304 BA stainless steel and 316 stainless steel plate for sale.

Understand the corrosion resistance of different grades in various environments, especially the suitability for specific application scenarios (such as marine environment, chemical industry, etc.).

Contact multiple stainless steel suppliers for quotes and availability. By comparing quotes from different suppliers, you can get an idea of the range of market prices. Investigate the supplier's background, credibility and history to understand the stability and reliability of their supply chain.

Ensure that the materials provided by suppliers comply with relevant international standards and certifications (such as ISO, ASTM, etc.) and have a reliable quality assurance system.

Understand the material's processability and weldability to ensure smooth manufacturing and assembly to meet production needs. 304 no 4 stainless steel can achieve high-quality thin plate welding through TIG welding, fast thick plate welding through MIG welding, flexible on-site welding through manual arc welding, and welding of thin plates and small workpieces through resistance welding.

Verify the chemical composition of the material to ensure it contains 18-20% chromium and 8-10.5% nickel to ensure corrosion resistance and mechanical properties.

Smelting equipment: Many Chinese stainless steel manufacturers have adopted advanced electric arc furnace (EAF), vacuum induction furnace (VIM) and vacuum arc remelting furnace (VAR) equipment to ensure high-purity and high-quality steel production.

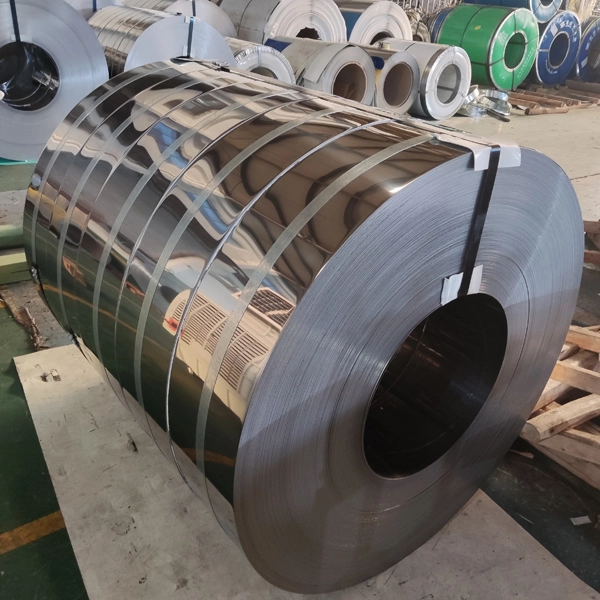

Rolling equipment: Modern hot and cold rolling equipment can produce stainless steel plates and strips with high precision and high surface quality.

Automated production lines: Many stainless steel manufacturers have introduced automated production lines, reducing manual operations and improving production efficiency and product consistency.

Smart manufacturing: Some leading companies have begun to apply Industry 4.0 technology to realize smart manufacturing through the Internet of Things (IoT), big data and artificial intelligence (AI) to further improve production efficiency and product quality.

Online testing: Use online testing equipment, such as X-ray fluorescence spectrometer (XRF), laser thickness gauge, etc., to monitor the chemical composition and dimensional accuracy of the product in real time.

Laboratory testing: Equipped with advanced laboratory testing equipment, such as scanning electron microscope (SEM), energy dispersive analyzer (EDS) and universal material testing machine, to conduct comprehensive quality testing and analysis.

Environmental protection technology: Many companies have adopted advanced environmental protection technology, such as exhaust gas treatment systems, waste water treatment systems and solid waste recycling systems, to reduce the impact of production on the environment.

Energy-saving technology: By optimizing production processes and equipment, we reduce energy consumption, improve resource utilization, and achieve green production.

Independent research and development: Many Chinese stainless steel production companies have dedicated R&D centers dedicated to the research and development of new materials, new processes and new technologies.

International cooperation: Some companies cooperate with internationally renowned research institutions and universities to conduct joint research and development of cutting-edge technologies to enhance technological innovation capabilities.

International standards: Chinese stainless steel manufacturers generally adopt international standards (such as ASTM, EN, JIS, etc.) for production to ensure that products meet the requirements of the global market.

Certification system: Many companies have passed international certifications such as ISO 9001, ISO 14001, and OHSAS 18001, and have established complete quality management systems and environmental management systems.

Hot topics that may interest you:

Which is more expensive 304 or 316 stainless steel

Which is stronger 304 or 316 stainless steel

What's the difference between 304 and 316 stainless steel

409 stainless steel vs 304 stainless steel