The 439 steel grade reduces the C content on the basis of the ordinary ferrite material (430), and at the same time adds Ti and other stabilizing elements to improve the intergranular corrosion resistance, formability and weldability of the steel grade. Compared with 304 steel, although its elongation is lower (about 30%), its strength and corrosion resistance are equivalent, and its corrosion resistance is better than that of 200 series materials.

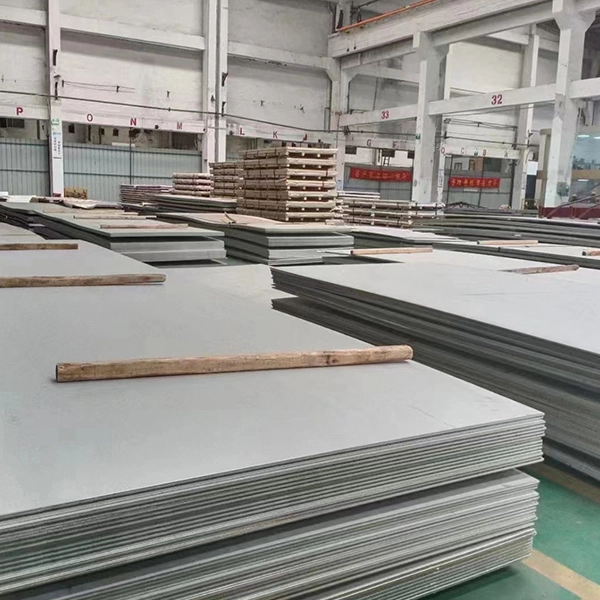

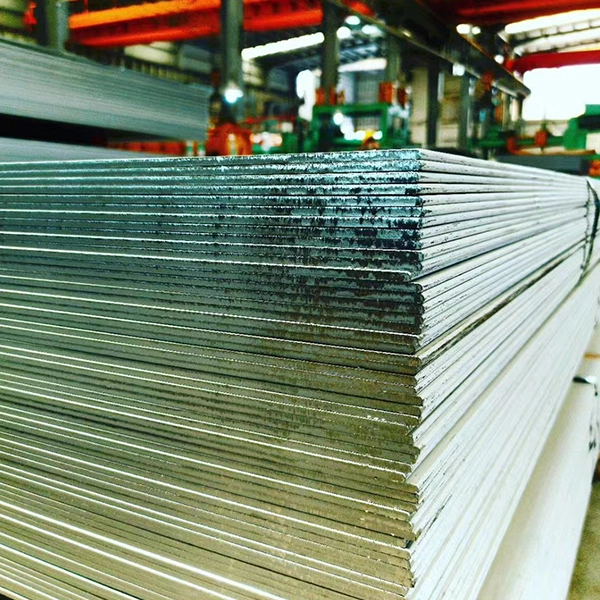

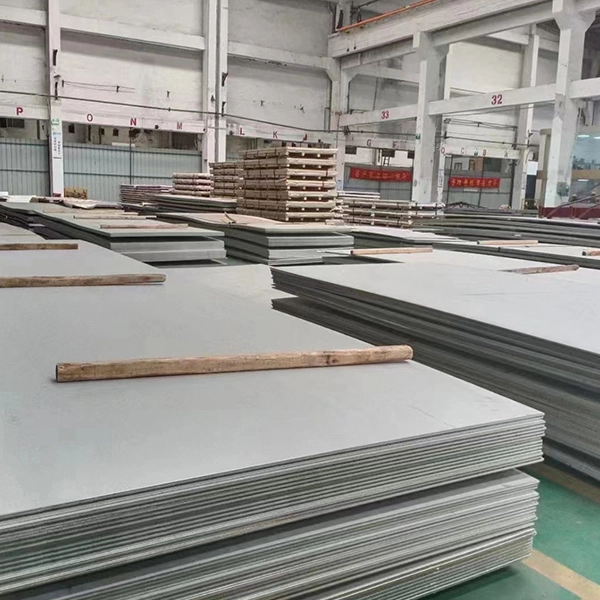

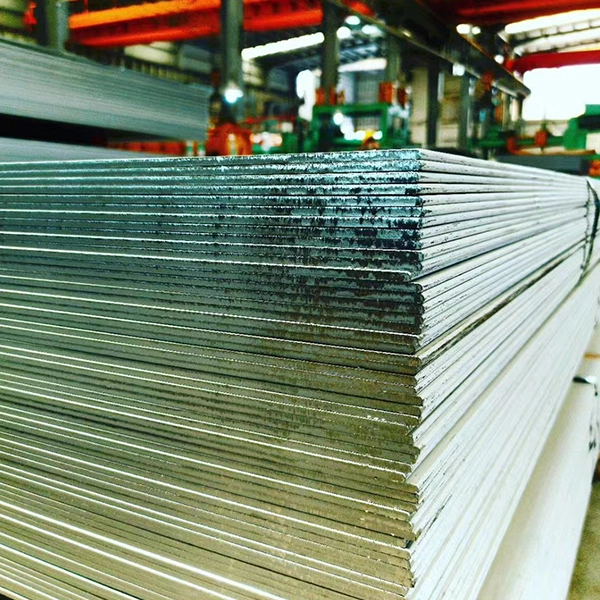

The strength of hot-rolled stainless steel is relatively low, and the surface quality is poor (with oxidation and low finish), but the plasticity is good, and it is generally a medium-thick plate. The hot-rolled stainless steel plate has low hardness, easy processing and good ductility. The mechanical properties are far inferior to cold working and inferior to forging, but have better toughness and ductility

| No.1 Finish Stainless Steel Plate Grades | 202 / 304 / 304L / 304H / 309S / 310S / 316 / 316L / 316Ti / 317L / 321 / 321H / 347 / 347H / 904L etc. UNS No. - UNS S30400, UNS S30403, UNS S31008, UNS S31620, UNS S31603, UNS S31603, UNS S31635, UNS S31703, UNS S32100, UNS S34700, UNS S34709, UNS S8904 EN No. - 1.4301, 1.4307, 1.4845, 1.4401, 1.4404, 1.4571, 1.4438, 1.4541, 1.4550, 1.4551, 1.4539 | |||

| Standard | JIS, AISI, ASTM, GB, EN | |||

| Place of Origin | China | |||

| Certification | ISO | |||

| Thickness Range | 3.0-80.0MM | |||

| Thickness Tolerance | ± 5%MM | |||

| Surface Classification | NO.1,1D,2D | |||

| Grade | / | |||

| Width | 1250 MM / 1500 MM / 2000 MM / 04 Feet / 05 Feet and Custom Cut Width as Per Requirement | |||

| Length | Steel Plate Length 2400 MM / 2420 MM / 6000 MM / 08 Feet / 10 Feet / Coil Cut and Custom Cut Length as Per Requirement | |||

| Technique | Hot Rolled | |||

| Quality | High Quality Inspection | |||

| Application | Automotive Railway & Transport Architecture, Building & Construction Chemical & Petrochemical Industries Pharmaceutical Energy and Power Oil and Gas Industries Kitchenware and Food Processing Industries Plumbing And Overhead Water Tanks | |||

| Brief Introdction | No.1 surface treatment is made by rolling stainless steel that has been heated before rolling (hot rolling). Subsequent heat treatment produces a uniform microstructure (annealing) and ensures that the stainless steel meets mechanical property requirements. After these treatment steps, the surface develops a dark, uneven appearance known as "scale". | |||

439 is a low-carbon stainless steel, usually containing diamond or steel, which has good corrosion resistance and heat resistance.

Standards: ASTM A240/A240M-18, EN 10088-2, JIS G4305, DIN EN 1.4510, etc.

characteristic:

Corrosion resistance: 439 stainless steel has good corrosion resistance and can resist water vapor, humidity, high temperature oxidation and some chemical substances, so it is often used at high temperatures.

Heat resistance: 439 stainless steel has good heat resistance in high temperature environments, and can withstand high temperatures up to 815°C.

Machinability: 439 stainless steel is easy to process, form and weld, and is often used in the manufacture of automobile exhaust systems.

Strength: 439 stainless steel tools have medium strength and hardness, and are suitable for some high-strength applications.

Application: 439 stainless steel coil for sale is widely used in automobile exhaust systems, home appliances, gas water heaters, chemical industry equipment and other fields.

Mechanical properties:

Stainless steel 439 has high yield strength and tensile strength, with a yield strength of about 310 MPa and a tensile strength of about 450 MPa.

439 steel has good ductility, with an elongation of more than 20%.

The hardness of 439 no.1 finish stainless steel is usually between 70 and 90 HRB.

439 stainless steel has good impact toughness at low temperatures.

AISI Type 439 (also known as ASTM XM-8) is a ferritic stainless steel designed to resist corrosion in a variety of oxidizing environments from fresh water to boiling acids. Type 439 is a titanium stabilized 18% chromium alloy that can be used in many oxidizing environments where Type 304 is considered adequate in terms of general corrosion resistance but is subject to chloride stress corrosion cracking. It is often used in place of Type 409 where higher thermal conductivity is required. Type 439 does not require annealing after welding to restore ductility or provide resistance to intergranular corrosion. Type 439 stainless steel strip for sale also has excellent formability and is widely used in the automotive industry; it can be slightly work hardened to increase tensile strength.