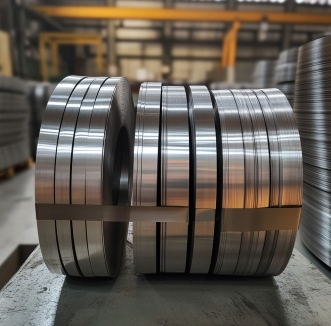

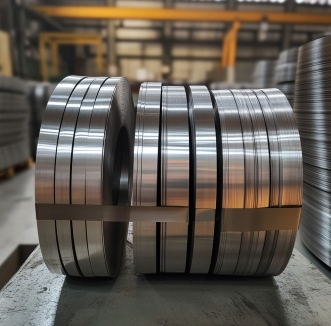

Introducing our wholesale 201 stainless steel strip, a premium product from Normandy Metal. This high-quality 201 stainless steel strip is known for its exceptional durability, strength, and corrosion resistance. Ideal for a wide range of applications across various industries, 201 stainless steel strip offers a perfect blend of performance and versatility. Choose Normandy Metal as your 201 stainless steel strip supplier for all your stainless steel needs and experience the superior quality of our 201 stainless steel strip.

| Product Name | 201 Stainless Steel Strip | |||

| Standard | JIS, AISI, ASTM, GB, EN | |||

| Place of Origin | China | |||

| Certification | ISO | |||

| Thickness Range | 0.3-10.0MM | |||

| Thickness Tolerance | ± 0-5%MM | |||

| Surface Classification | NO.1,1D,2D, 2B, N0.4, HL, BA, Mirror, and various other surface treatment states. | |||

| Grade | 200 Series | |||

| Width | 20-1530mm | |||

| Length | as per client's requirement | |||

| Technique | Cold Rolled & Hot Rolled | |||

| Quality | High Quality Inspection | |||

| Application | 201 Stainless Steel Strip, has a certain acid, alkali resistance, high density, polishing without bubbles, no pinhole and other characteristics, is the production of various watchcase, strap cover high quality materials, etc... | |||

| Brief Introdction | 201 stainless steel strip, with certain acid and alkali resistance, high density, polished without bubbles, no pinholes, etc., is a high-quality material for the production of various watch cases and strap bottom covers. 201 wholesale stainless steel strip is mainly used to make decorative pipes, industrial pipes, and some shallow stretched products. | |||

201 stainless steel strip is a kind of manganese-chromium-nickel stainless steel, which usually contains about 5.5-7.5% manganese, 16-18% chromium and 3.5-5.5% nickel, in addition to nitrogen and other elements. Compared with other stainless steels, 201 stainless steel strip has lower nickel content, which makes its price more economical. 201 stainless steel strip has good corrosion resistance, heat resistance and mechanical properties, and can be used to manufacture various products, such as kitchen utensils, household goods, building materials, chemical equipment, etc. 201 stainless steel strip is also often used to replace 304 stainless steel, because it costs less but still has similar corrosion resistance and strength. 201 stainless steel strip is usually suitable for low to moderate corrosive environment, such as indoor environment or non-seawater conditions.

1. 2B Finish: This finish is the most commonly used and is characterized by a smooth, reflective surface.

2. BA Finish: This is a mirror-like finish that provides bright annealed stainless steel high reflectivity.

3. No.4 Finish: No 4 stainless steel has a brushed appearance and provides a duller, less reflective surface.

4. Hairline Finish: This finish is characterized by a long, narrow line pattern and provides anti-fingerprint stainless steel a subtle, decorative effect.

5. Embossed Finish: This finish has a textured surface with raised patterns that create a decorative effect.

6. Etched Finish: This finish has a patterned surface created by acid etching, providing a decorative finish.

We use advanced cold rolling technology and fine polishing to make 201 stainless steel strip achieve mirror-like gloss and flawless surface. Every production link is strictly monitored, from the selection of raw materials to the inspection of the final product, to ensure that each roll of stainless steel strip meets high standards of quality. Operated by experienced technicians, every detail of the cutting process is strictly controlled. In addition, high-quality cutting tools are used to maintain sharpness and durability, reducing burrs and irregular edges generated during the cutting process of 201 stainless steel strip.

201 stainless steel strip is mainly used in high temperature applications, which require the material to have strong anti-sensitization properties to prevent intergranular corrosion at lower temperatures. Uses: Applied to field machines in the chemical, coal and petroleum industries that require high resistance to grain boundary corrosion, heat-resistant parts of building materials and parts that are difficult to heat treat;

Petroleum waste gas combustion pipeline | Engine exhaust pipe | Boiler shell, heat exchanger, heating furnace parts | Silencer components for diesel engines |

Boiler pressure vessel | Chemical transport vehicles | Expansion joints | Spiral welded pipes for furnace pipes and dryers |

We are a trusted 201 stainless steel strip supplier, renowned for our ability to support custom specifications. Whether you need unique dimensions or specific finishes, our team is ready to meet your exact requirements. In addition to our custom services, we maintain a robust inventory of standard-size wholesale 201 stainless steel strip to ensure quick availability. Our extensive stock allows us to fulfill orders promptly, minimizing your wait time. We pride ourselves on our fast shipping capabilities, ensuring that your materials arrive on schedule.